Fahrrad

Dieser All-Condition-Reifen kombiniert ein rundes Profil, das rauen Straßenbelägen den Schrecken nimmt, mit einer Konstruktion, die maximale Kontrolle und geringen Rollwiderstand bietet.Handgefertigte Reifen kombinieren viele Eigenschaften, um die komfortabelsten Reifen mit geringem Rollwiderstand zu schaffenPPS: Der Pannenschutzstreifen ist ein spezielles Gewebe, das zwischen der Lauffläche und der Karkasse des Reifens angebracht wird, um die Widerstandsfähigkeit gegen Reifenpannen zu erhöhen.Druck: 5 - 6,5 BARSicherheitsgrenze: 1000 KPAWarnung: Tubeless Ready-Reifen (mit TLR gekennzeichnet) können mit oder ohne Schlauch montiert werden. TLR-Reifen sind nur für den schlauchlosen Betrieb mit einem Dichtmittel ausgelegt. Die Reifen sind gemäß den ETRTO-Standards für Felgenbreite und Druck (max. Druck 500kPa/5 bar/75 psi) hakenlos kompatibel. Dies gilt nur für Handmade Tubeless Ready (H-TLR)-Reifen ab 33 mm.

Dieser All-Condition-Reifen kombiniert ein rundes Profil, das rauen Straßenbelägen den Schrecken nimmt, mit einer Konstruktion, die maximale Kontrolle und geringen Rollwiderstand bietet.Handgefertigte Reifen kombinieren viele Eigenschaften, um die komfortabelsten Reifen mit geringem Rollwiderstand zu schaffenPPS: Der Pannenschutzstreifen ist ein spezielles Gewebe, das zwischen der Lauffläche und der Karkasse des Reifens angebracht wird, um die Widerstandsfähigkeit gegen Reifenpannen zu erhöhen.Druck: 5 - 6,5 BARSicherheitsgrenze: 1000 KPAWarnung: Tubeless Ready-Reifen (mit TLR gekennzeichnet) können mit oder ohne Schlauch montiert werden. TLR-Reifen sind nur für den schlauchlosen Betrieb mit einem Dichtmittel ausgelegt. Die Reifen sind gemäß den ETRTO-Standards für Felgenbreite und Druck (max. Druck 500kPa/5 bar/75 psi) hakenlos kompatibel. Dies gilt nur für Handmade Tubeless Ready (H-TLR)-Reifen ab 33 mm.

Dieser All-Condition-Reifen kombiniert ein rundes Profil, das rauen Straßenbelägen den Schrecken nimmt, mit einer Konstruktion, die maximale Kontrolle und geringen Rollwiderstand bietet.Handgefertigte Reifen kombinieren viele Eigenschaften, um die komfortabelsten Reifen mit geringem Rollwiderstand zu schaffenPPS: Der Pannenschutzstreifen ist ein spezielles Gewebe, das zwischen der Lauffläche und der Karkasse des Reifens angebracht wird, um die Widerstandsfähigkeit gegen Reifenpannen zu erhöhen.Druck: 5 - 6,5 BARSicherheitsgrenze: 1000 KPAWarnung: Tubeless Ready-Reifen (mit TLR gekennzeichnet) können mit oder ohne Schlauch montiert werden. TLR-Reifen sind nur für den schlauchlosen Betrieb mit einem Dichtmittel ausgelegt. Die Reifen sind gemäß den ETRTO-Standards für Felgenbreite und Druck (max. Druck 500kPa/5 bar/75 psi) hakenlos kompatibel. Dies gilt nur für Handmade Tubeless Ready (H-TLR)-Reifen ab 33 mm.

Der Elite Pro : Handgefertigte Reifen kombinieren viele Eigenschaften, um die komfortabelsten Reifen mit geringem Rollwiderstand zu schaffen. PPS: Der Pannenschutzstreifen ist ein spezielles Gewebe, das zwischen der Lauffläche und der Karkasse des Reifens angebracht wird, um die Widerstandsfähigkeit gegen Pannen zu erhöhen. Karkasse: SuperPoly Druck: 5,5 - 7,5 BAR Sicherheitsgrenze: 1000 KPA

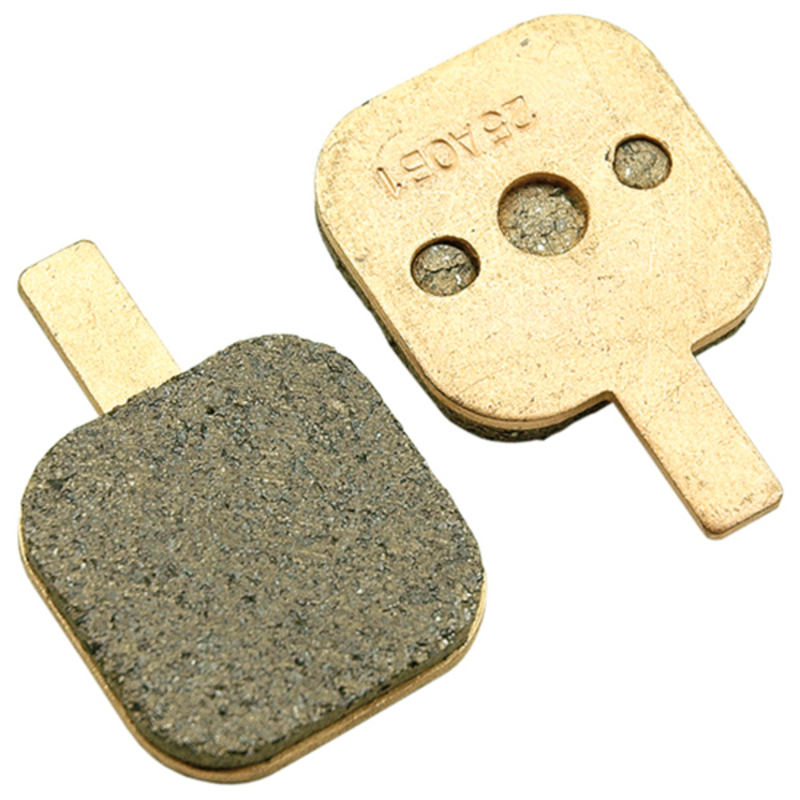

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.Only sintered metal pads can respond to evert needs of the most demanding rider:High braking powerLow heatingGood reaction to low temperaturesUse under water, mud and dustWithout noiseThese are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health.Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The tablet is rectified, controlled and packaged under careful processes and ISO quality standards.CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition by numerous DH and XC world class teams.VRX finish:For Rally, XC, Enduro, AM use.Ceramic casing (white in color located on the part that contacts the caliper piston) that reduces the temperature of the brake assembly for perfect performance.Excellent Grip. Long life and reduced disc wear. No fading, no noise.